Fire Ember Guard

Living in bush-surrounded areas does have its advantages of a rural lifestyle but also the disadvantages that generally these areas are high fire risk zones.

During a fire burning embers are created and if the conditions are windy become airborne, depending on how windy it is these burning embers can travel some distance before settling down and spreading the fire risk. When these embers land on roofs and gutters if there are dry leaves and debris build up there is a potential risk of ignition and starting a fire which can spread under the roof to the roof frame and then to the rest of the home.

Special gutter guard has been developed to help combat this problem. Ember Guard a 2mm superfine all steel mesh is fitted to the gutter edge and to the roof virtually eliminating any gaps for burning embers to enter. This is custom made and suits all types of roofs.

Don’t be fooled by plastic mesh that salespeople flog off as fireproof, Gutter Knight’s product is Ember Guard Compliant; high performing, Australian made gutter mesh that meets the New Australian Standard requirements for Ember Guards. Made from quality steel that has been hot galvanised dipped and then powder-coated in a colour to match your roof.

If you live in a bushfire prone area or are building in one, contact us and find out how Gutter Knight’s Ember Guard can help you and your family keep safe.

Some great additional benefits

How our all Steel Gutter Mesh is installed

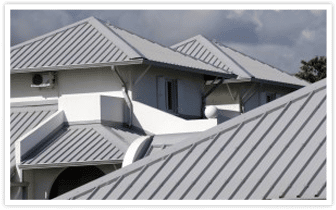

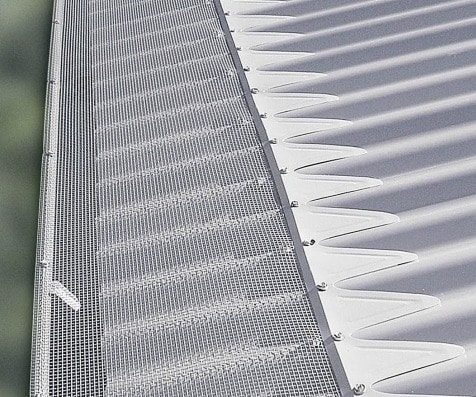

Metal roofs

The all-steel gutter mesh lays totally flat on the roof and is secured to the top of the gutter edge with the use of a metal trim that has been powder-coated to match the gutter and this is held in place with galvanised screws. The other side of the mesh is secured to the roof using a custom steel profile that is also held in place with galvanised self-sealing screws. This forms a tightly enclosed area that easily lets water in but keeps leaves and debris out as they just slide or blow off with the wind.

For a seamless and neat finish, all fittings and gutter mesh used are powdered coated to suit the colour of your roof and gutters.

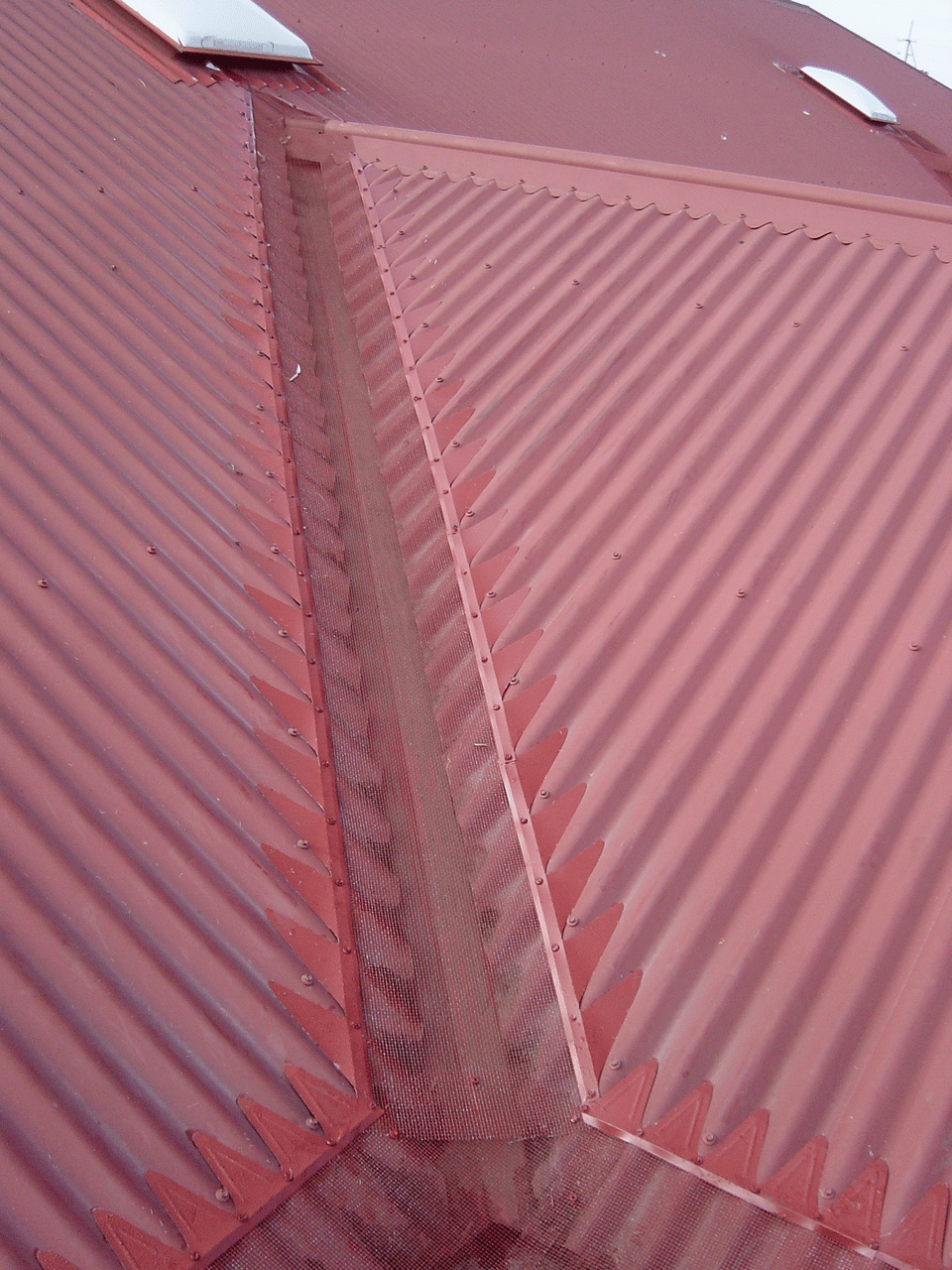

Metal roof valleys

Valley mesh: The all steel gutter mesh is laid totally flat across the top of the valley and custom-made profiles to suit the pitch of the roof are installed on either side with galvanised self-sealing screws.

Valley dome: specially manufactured steel dome mesh to fit the width of your valleys is inserted and secured into place by using the tension held within the mesh

Both these methods protect the valleys and also tie into the lower gutter guard at the bottom to form an entire enclosed system.

Tiled roofs

The all steel gutter mesh is secured to the top of the gutter edge with the use of a metal trim that has been powder-coated to match the gutter and this is held in place with galvanised screws. The other side of the mesh is secured up under the base of the second tile back, or secured using steel clips.

When installed the gutter guard mesh has a downward slope over the outside edge of your gutters allowing leaves and debris to simple slide or blow off with the wind.

For a seamless and neat finish all fittings and gutter mesh used are powdered coated to suit the colour of your roof and gutters.

Tiled valleys

Valley dome: specially manufactured steel dome mesh to fit the width of your valleys is inserted and secured into placed by using the tension held within the mesh. This protects the valleys and also ties into the lower gutter guard at the bottom to form an entire enclosed system.